Your expert in thermoforming machines, extrusion lines, and plastic cup making machines, engineered for efficient and reliable plastic packaging production

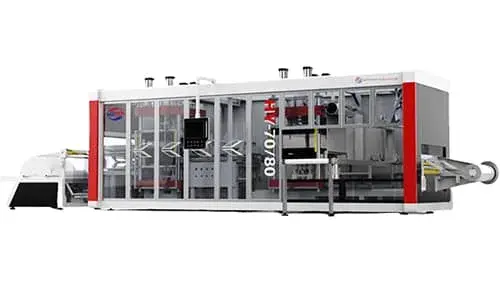

In-mold-cut thermoforming machine for the production of plastic food trays, containers, lids, boxes, etc.

Form-cut-stack thermoforming machine for the production of plastic plates, trays and food containers

This category of plastic cup making machines cover processes of thermoforming, rim rolling, printing, stacking and packaging of disposable plastic cups and lids.

Our plastic sheet extrusion lines are engineered to transform raw plastic pellets into high-quality sheets and roll stock ready for thermoforming

Discover reliable plastic processing machines for disposable plastic containers - connect with our experts today!

Our thermoforming machines can produce a wide range of containers used for hot & cold ready-to-eat meals, takeaway food, fresh fruit, vegetable and meal, bakery bread, cookie, snacks, and other packaged foods. They are also suitable for manufacturing disposable tableware items, such as trays, plates, plastic cutlery trays.

Our plastic cup thermoforming machines can manufacture a variety of plastic cups and matching lids, meeting the packaging needs of beverage producers.

Our thermoforming machines can produce plastic containers for daily-use products, as well as small industrial parts packaging boxes and electronic component trays.

Yes, we supply distributors with product manuals, multi-angle images, demonstration videos, and case studies. These materials include equipment specifications, application scenarios, and customer cases, and can be provided free of charge to support market promotion. AMTOP

Yes, our overseas service team offers on-site installation and commissioning to ensure proper connection of mechanical, electrical, and pneumatic systems. We also train operators on parameter settings, daily maintenance, and operation, ensuring smooth and reliable use of the machines.

If flexibility and lower investment costs are priorities, and local labor costs are relatively low, a single-station thermoforming machine is a practical choice. It allows for easy mold changes and the ability to produce different products while keeping initial investment affordable.

For large-scale production, multi-station thermoforming machines are generally the superior choice. Leveraging the advantage of multiple stations operating simultaneously, they achieve higher output and a far greater degree of automation than single-station models.

However, we must not overlook the specific characteristics of the product. We must recommend the most suitable machine type to the customer based on the final product requirements they provide.