The plastic cup packaging machine is an automated system designed for efficient counting and packaging of disposable plastic cups. The integrated cup counter separates cup stacks and prepares them for wrapping, ensuring fast, accurate, and hygienic packaging.

| Model |

|

| Packaging Rows | 1, 2, 3, or 4 (optional) |

| Cup diameter | 55-100mm |

| Packaging speed | 20-50 bag/min |

| Packaging length | 260-800mm |

| Packaging width | 250-450mm |

| Voltage | 220V, 50Hz (can be customized) |

| Power | 3.5kW |

| Packaging material | OPP/HDPE heat sealing film |

| Packaging film thickness | 0.02-0.06mm |

| Machine dimensions (L×W×H) | 5500×1000×1500mm |

| Machine weight | 600kg |

Controlled by PLC program, integrating stacking, counting, bag/film sealing, and cutting. (Optional date printer available)

Equipped with high-quality components from international brands for pneumatic elements, PLC, and frequency inverters

Compact structure with stable operation and easy controls. Features include dual frequency inverter control, random bag length cutting, and PID temperature control, suitable for various packaging films

Double-servo cup counter with dual-way counting system for higher output efficiency

Adjustable production speed, with cup counting range from 1 to 100

Plastic cup packaging machine

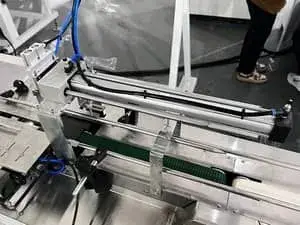

Plastic cup packaging machine Cup feeding section

Cup feeding section Cup counting section

Cup counting section  Sealing section

Sealing section Film feeding roll

Film feeding roll Film traction system

Film traction system Cups discharge conveyer

Cups discharge conveyer Finished packaged cups

Finished packaged cups

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Typically, plastic cups and bowls are manufactured from highly transparent materials such as polypropylene (PP) and polyethylene terephthalate (PET). This demands exceptionally high standards in stretch forming technology, and our thermoforming machines for plastic cups can provide customers with production capabilities.

Yes, ice cream cup is made from PET material, this plastic cup forming machine supports thermoforming processes using polyethylene terephthalate (PET) materials, ensuring compliance with the hygiene standards and transparency requirements necessary for food packaging. It can be used to manufacture ice cream cups in a variety of complex shapes.