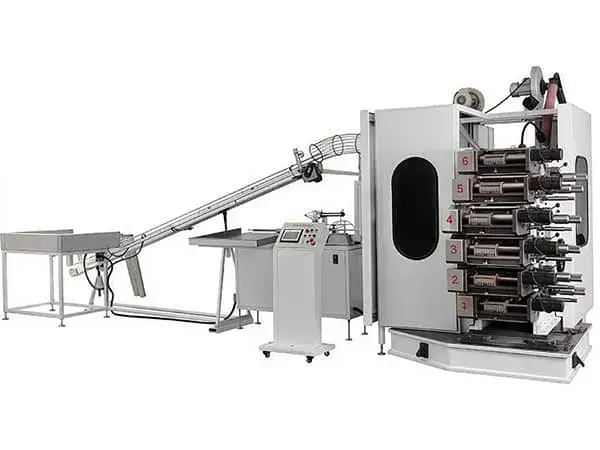

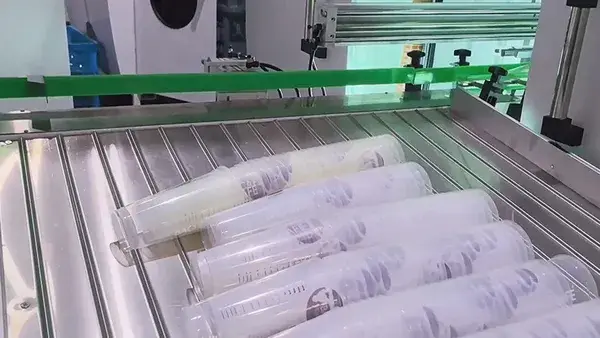

This high-performance printing machine is designed for multi-color pattern printing on plastic cups and containers made from PP, PS, PET, PLA, and HDPE. It supports up to 8-color printing with a maximum speed of 330 cups per minute, making it ideal for large-scale production.

The plastic cup printing system is widely used for yogurt cups, ice cream cups, fast-food bowls, beverage cups, and other cylindrical or conical plastic products. It integrates a full automation process including cup feeding, printing, quality inspection, and counting, ensuring efficiency, accuracy, and consistency in every production run.

| Model |

|

| Print colors | 4/6/8 colors |

| Max. printing depth | 158mm |

| Cup depth | 50-180mm |

| Cup body slope | 5-12 degree |

| Max. printing speed | 200-330cups/min (depending on cup size and material) |

| Cup material | PP/PS/PET/PLA/HDPE |

| Cup rim diameter | 40-180mm |

| Main motor power (two motors) | 8kW |

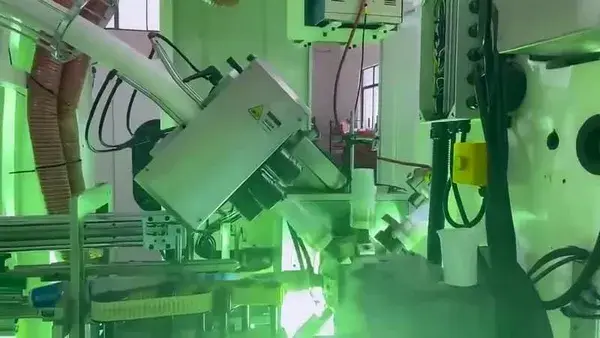

| UV curing power | 6kW |

| Total power | 21kW |

| Machine weight | Approx. 5.1t |

| Machine dimensions (L×W×H) | 6200×2500×2660mm |

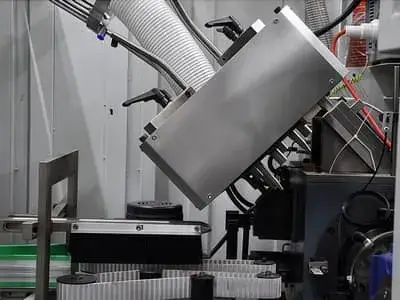

Automatic incline-type cup feeder, convenient to operate and adaptable for various cup types

Adjustable cup feeding separator ensures smooth and precise transfer into the printer

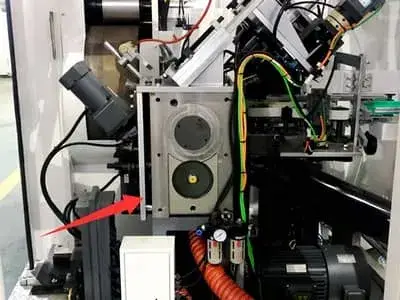

Roll gearbox with automatic distance adjustment eliminates shadows on the cup surface

Printing plate with specialized punch allows quick alignment and easy operation

Fast and convenient replacement of mold cores or cup molds

Corona inspection system detects defective cups

Sampling inspection function for quality assurance during operation

Servo motor-controlled automatic counting for higher accuracy and easy cup collection

For thermoformed cups, the printing machine employs an inclined feed system; for injection-moulded cups, it utilises an upright trapezoidal feed system to ensure smooth and reliable cup conveyance.

High-precision feeding system that guarantees stable operation at high speeds, maintaining accuracy and consistency.

Printing zone can be adjusted for 1-6 colors based on customer requirements.

Pre-corona treatment of the cups before printing to improve ink adhesion and achieve better color quality.

Equipped with high-quality SANDEX (Japan) indexing unit, providing long-term durability and reliable performance.

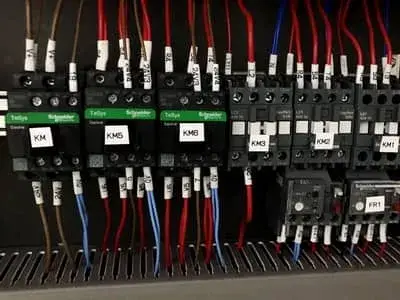

Electric witches and controllers from the well-known brand Schneider (France) ensure stability, reliability and safety.

Integrated Siemens PLC module for precise and efficient machine control.

Every machine is fully assembled and tested before delivery to guarantee performance and reliability.

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Typically, plastic cups and bowls are manufactured from highly transparent materials such as polypropylene (PP) and polyethylene terephthalate (PET). This demands exceptionally high standards in stretch forming technology, and our thermoforming machines for plastic cups can provide customers with production capabilities.

Yes, ice cream cup is made from PET material, this plastic cup forming machine supports thermoforming processes using polyethylene terephthalate (PET) materials, ensuring compliance with the hygiene standards and transparency requirements necessary for food packaging. It can be used to manufacture ice cream cups in a variety of complex shapes.