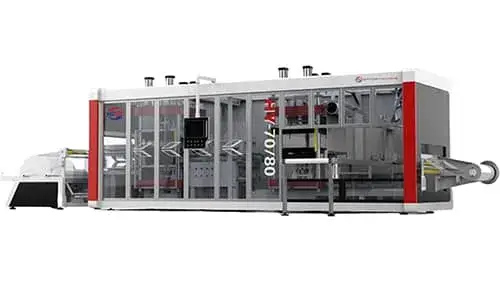

The multi-station thermoforming machine integrates forming, cutting, and stacking for efficient production of plastic plates, trays, egg trays, and food containers, delivering uniform thickness, high output, and reliable automation.

The plastic thermoforming machine is engineered for a wide range of thermoplastics, including PET, BOPS, PS, PVC, and PLA.

This multi-station thermoforming machine is designed to process PS, PP, PVC, PET, HIPS, and other plastic sheets into a wide range of shapes, including circular, square, and irregular products.

This three-station plastic vacuum forming machine uses negative vacuum pressure for molding.

Thermoforming molds for multi-station machines include forming, punching, cutting, and stacking dies, with tooling life of up to 1.5 million cycles and 60-80% material utilization for plastic packaging production.

Discover reliable plastic processing machines for disposable plastic containers - connect with our experts today!

Yes, our thermoforming machine is equipped with an intelligent temperature control system. It offers automatic fault diagnosis, data storage for up to 1,000 sets, and real-time monitoring, helping detect issues early and minimize production loss.

A multi-station plastic thermoforming machine with positive and negative pressure forming is recommended. It can handle complex structures while delivering more uniform wall thickness, ensuring better accuracy and sealing performance.

The plastic thermoforming machine with positive and negative pressure forming is the preferred choice. It provides more uniform thickness and better material distribution, producing smoother surfaces and reducing internal stress. This results in higher transparency for finished products.

Start-ups typically develop a wide variety of products, at which point the demands on moulding costs are extremely high.

The multi-station plastic vacuum (negative pressure) forming machine is a practical choice. It has a simpler structure, lower investment cost, and easier operation and maintenance. While suited for less complex containers, it still supports efficient production.

Lunch takeaway boxes are typically manufactured from polypropylene (PP) material.

Should the factory require precise die-cutting with no burrs along the outer edges, we recommend employing single-station in-mould trimming machines.

Recommend HY-54/76 (760×540mm) or ATC-75/52 (750×520mm) models.

Where production volume demands take precedence over die-cutting precision, we advise utilising multi-station forming machines.

Recommend ATM-76/65 (760×650mm) or ATM-75/85 (750×850mm) models.

Our negative pressure three-station thermoforming machine boasts extensive case studies demonstrating its highly successful capability to simultaneously perform trimming, punching, and waste removal during the punching station for PS/PET products.