This plastic thermoforming machine can process PP, HIPS, PS, PVC, and PET sheets into a wide variety of shapes, including circular, square, and irregular designs. It is ideal for manufacturing packaging products such as boxes, plates, trays, bowls, lids, and more. Applications cover food packaging, industrial packaging, and cosmetic packaging, making it a versatile solution for different sectors.

| Model |

|

|

| Max. forming area | 760×540mm | |

| Max. forming depth | 100mm (pick product from inside the mold) | |

| 120mm (pick product from outside the mold) | ||

| Sheet thickness | 0.2-1.5mm | |

| Production speed | 600-1500cycles/hr | |

| Heating power | 132kW | |

| Motor power | 33kW | |

| Air pressure | 0.7MPa | |

| Air consumption | 3000 liters/min | |

| Water consumption | 70 liters/min | |

| Power supply | 3 phase, AC 380±15V, 50Hz | |

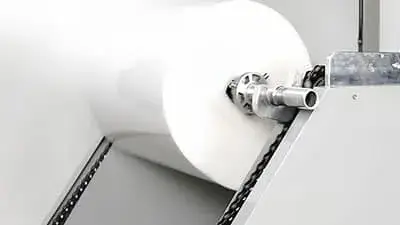

| Sheet roll diameter | 1000mm | |

| Machine weight | 9000kg | |

| Dimensions (L×W×H) | Main machine | 6500x2020x2400mm |

| Material feeder | 1500×1420×1450mm | |

Material feeding, heating, forming, cutting, and stacking integrated in one machine

You can choose the in mold grasping method to ensure that there are no hanging points around the product and improve the product quality standards

Forming and punching in the same workstation, simplifying operation and improving accuracy

Servo control system ensures smooth, stable, and consistent performance

In-mold cutting delivers precise punching with zero error, ideal for pure PP products

High material utilization, with low air consumption and reduced maintenance needs

Stable capacity, making the machine suitable for continuous, large-volume production

User-friendly PLC touchscreen for easy operation and control

Motor and driver

Motor and driver Electrical component

Electrical component Vacuum pump

Vacuum pump Control valve

Control valve

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Our thermoforming machines can produce a wide range of containers used for hot & cold ready-to-eat meals, takeaway food, fresh fruit, vegetable and meal, bakery bread, cookie, snacks, and other packaged foods. They are also suitable for manufacturing disposable tableware items, such as trays, plates, plastic cutlery trays.

Our plastic cup thermoforming machines can manufacture a variety of plastic cups and matching lids, meeting the packaging needs of beverage producers.

Our thermoforming machines can produce plastic containers for daily-use products, as well as small industrial parts packaging boxes and electronic component trays.

Yes, we supply distributors with product manuals, multi-angle images, demonstration videos, and case studies. These materials include equipment specifications, application scenarios, and customer cases, and can be provided free of charge to support market promotion. AMTOP

Yes, our overseas service team offers on-site installation and commissioning to ensure proper connection of mechanical, electrical, and pneumatic systems. We also train operators on parameter settings, daily maintenance, and operation, ensuring smooth and reliable use of the machines.