With a material utilization rate of up to 93% and low energy consumption of just 8 kW/h, this roll-fed single-station thermoforming machine helps significantly reduce production costs and enhance your market competitiveness.

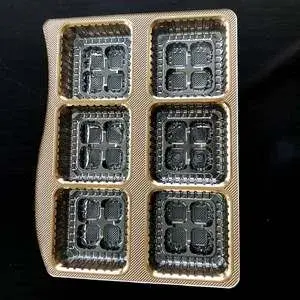

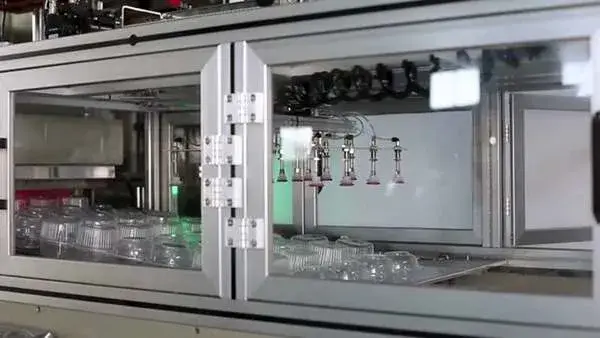

The plastic thermoforming machine efficiently processes BOPS, PET, HIPS, PS, and PVC roll sheets into various disposable packaging products, including fast-food boxes, dishes, lids, cookie trays, and other containers. It integrates feeding, heating, forming, cutting, and stacking into one seamless operation, delivering high productivity and consistent quality.

| Model |

|

|

|

| Forming area | 510×620mm | 630×780mm | 700×950mm |

| Forming depth | 100mm | 125mm | 125mm |

| Applicable material | BOPS/PET/PVC/HIPS | BOPS/PET/PVC/HIPS | BOPS/PET/PVC/HIPS |

| Sheet thickness | 0.1-1mm | 0.12-1mm | 0.15-1mm |

| Cutting knife length | 6.8m for PET/ 10m for OPS | 9m for PET/ 11m for OPS | 12m for PET/ 18m for OPS |

| Sheet roll diameter | 710mm | 800mm | 1000mm |

| Max. sheet width | 680mm | 810mm | 1000mm |

| Air pressure | 0.7MPa | 0.7MPa | 0.7MPa |

| Water consumption | 5 liters/min (15-20℃) |

8 liters/min (15-20℃) |

15 liters/min (15-20℃) |

| Air consumption | 1500 liters/min | 2000 liters/min | 2400 liters/min |

| Production speed | 600-1200 cycles/hr | 600-1200 cycles/hr | 600-1200 cycles/hr |

| Voltage | AC380V±15V, 50Hz | AC380V±15V, 50Hz | AC380V±15V, 50Hz |

| Total heating power | 24kW | 40kW | 50kW |

| Total motor power | 8kW | 9kW | 12kW |

| Approx. power consumption | 7.5kW/hr | 10kW/hr | 14kW/hr |

| Machine weight | 3500kg | 5200kg | 7000kg |

| Machine dimensions (L×W×H) | 5×1.55×2.35m | 5.6×1.75×2.5m | 6.6×1.75×2.7m |

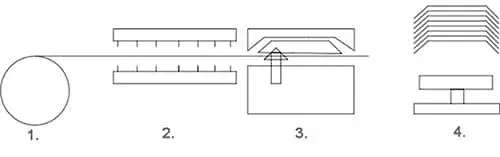

Feeding

Feeding Pre-heating

Pre-heating Heating, Forming & Cutting

Heating, Forming & Cutting Counting & Stacking

Counting & Stacking

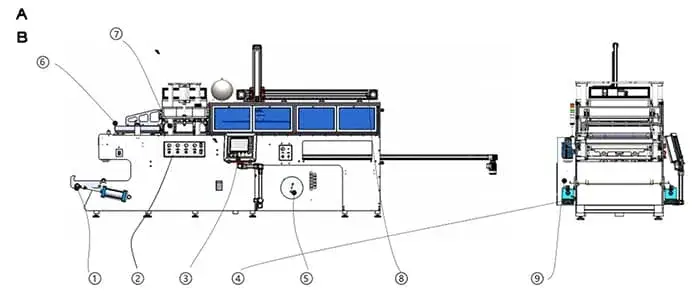

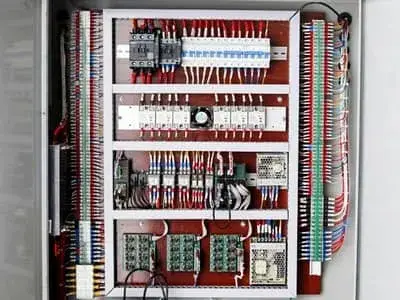

A: Three-phase power connection is inside the electrical cabinet.

B: Cooling water inlet is below right side of electrical cabinet, the air supply connection is at the back, above the winding rack.

Forming and cutting in a single station with precise, error-free cutting

High material utilization with a usage rate of 80-95% and defect levels as low as 5-20%

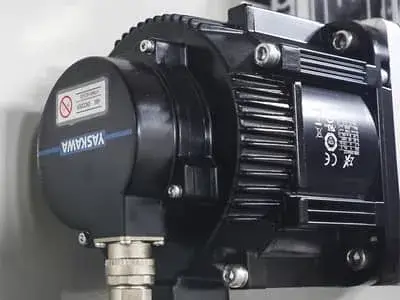

Full servo control system designed for energy savings, with reduced noise and lower air consumption

With low power consumption of around 7-14 kW/h, it helps reduce energy costs. The heating wires provide rapid heating while maintaining high energy efficiency.

User-friendly operation, allowing one operator to manage the station, reducing labor requirements

We can customize A/B staggered stacking and 90/180 degree rotation stacking methods. The robot arm can efficiently stack even irregularly placed products

PLC

PLC Servo system

Servo system Air valve

Air valve Electrical switches

Electrical switches

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Our thermoforming machines can produce a wide range of containers used for hot & cold ready-to-eat meals, takeaway food, fresh fruit, vegetable and meal, bakery bread, cookie, snacks, and other packaged foods. They are also suitable for manufacturing disposable tableware items, such as trays, plates, plastic cutlery trays.

Our plastic cup thermoforming machines can manufacture a variety of plastic cups and matching lids, meeting the packaging needs of beverage producers.

Our thermoforming machines can produce plastic containers for daily-use products, as well as small industrial parts packaging boxes and electronic component trays.

Yes, we supply distributors with product manuals, multi-angle images, demonstration videos, and case studies. These materials include equipment specifications, application scenarios, and customer cases, and can be provided free of charge to support market promotion. AMTOP

Yes, our overseas service team offers on-site installation and commissioning to ensure proper connection of mechanical, electrical, and pneumatic systems. We also train operators on parameter settings, daily maintenance, and operation, ensuring smooth and reliable use of the machines.