We operate three specialized workshops to ensure efficient and precise production. Workshop 1 focuses on single-station thermoforming machines, workshop 2 manufactures plastic cup forming machines and plastic sheet extrusion lines, while workshop 3 is dedicated to multi-station thermoforming machines. Before making an inquiry, customers are encouraged to share their intended product requirements with our team. This allows us to recommend the most suitable machines and services, precisely matched to your requirements and designed to deliver the best results for your production.

To provide greater flexibility and value, we have transitioned from outsourcing molds to producing them in-house. Today, we operate eight high-precision machining centers exclusively for mold manufacturing. In-house production not only lowers costs for customers but also allows us to integrate user feedback more effectively into mold design. Should adjustments be required, our team can quickly carry out modifications, ensuring efficiency, precision, and better service for every client.

Every thermoforming, extrusion and packaging machine undergoes a comprehensive inspection before shipment, with detailed reports provided to the customer for confirmation. Once approved, we work closely with clients to arrange safe delivery. Prior to dispatch, each machine for thermoforming process to make plastic packaging is carefully tested, treated with anti-rust protection, and reinforced for transport. Rainproof film and additional supports are applied during loading to ensure that the equipment arrives in perfect condition at its destination.

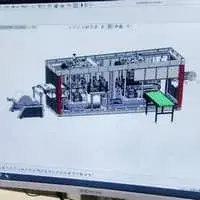

Machine design and drawing

Machine design and drawing

Production workshop operations

Production workshop operations

Crafting process

Crafting process

CNC mold grinding

CNC mold grinding

Welding work

Welding work

Assembly

Assembly

Electrical installation

Electrical installation

Testing and calibration

Testing and calibration

Sample verification

Sample verification

Packaging and shipment

Packaging and shipment

Discover reliable plastic processing machines for disposable plastic containers - connect with our experts today!