With an impressive material utilization rate of 65-90% and energy-efficient operation consuming just 15-20 kW/h, this 3-station thermoforming machine helps reduce production costs while enhancing your competitive edge.

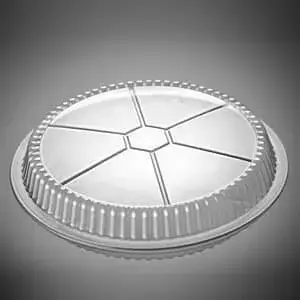

The plastic thermoforming machine is engineered for a wide range of thermoplastics, including PET, BOPS, PS, PVC, and PLA. It efficiently manufactures diverse packaging products such as bowls, plates, lids, trays, punnets, fruit and vegetable boxes, food containers, and blister trays for wine, pharmaceuticals, electronics, and everyday items.

| Model |

|

|

| Max. forming area | 700×800mm | |

| Applicable materials | BOPS/PET/HIPS/PVC | |

| Max. forming depth | 120mm | |

| Sheet thickness | 0.1-1.0mm | |

| Max. cutting force | 70T | |

| Production speed | 14-25 cycles/min | |

| Total heating power | 20kW (A zone) 36kW (B zone) | |

| Total motor power | 22kW | |

| Air pressure | 0.7MPa | |

| Air consumption | 3000 liters/min | |

| Water consumption | 50 liters/min | |

| Power supply | AC380+15V, 50Hz | |

| Max. sheet roll diameter | 1000mm | |

| Machine weight | 10000kg | |

| Dimensions (L×W×H) | Main machine | 7670×1705×2830mm |

| Material feeder | 1440×1323×1306mm | |

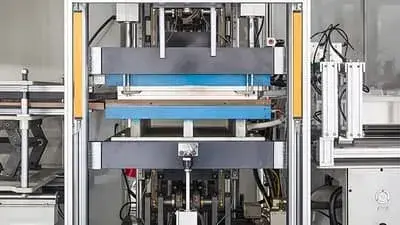

Three-station design integrates automatic forming, cutting, and stacking for high efficiency

Full servo drive system ensures stable and precise machine operation

Memory storage system simplifies operation and parameter adjustment

Dual heating systems, one optimized for BOPS sheets and one for PET sheets, ensuring best forming quality

Chain-free feeding system increases material utilization to 65-90%

Cost-effective molds with simple, efficient design for easier maintenance

Energy-efficient operation with high-performance heating rods, power consumption approx. 15-20kW/h

Solenoid valve

Solenoid valve PLC multi-color touch screen

PLC multi-color touch screen Servo motor and drive

Servo motor and drive Circuit breaker

Circuit breaker

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Yes, our thermoforming machine is equipped with an intelligent temperature control system. It offers automatic fault diagnosis, data storage for up to 1,000 sets, and real-time monitoring, helping detect issues early and minimize production loss.

A multi-station plastic thermoforming machine with positive and negative pressure forming is recommended. It can handle complex structures while delivering more uniform wall thickness, ensuring better accuracy and sealing performance.

The plastic thermoforming machine with positive and negative pressure forming is the preferred choice. It provides more uniform thickness and better material distribution, producing smoother surfaces and reducing internal stress. This results in higher transparency for finished products.

Start-ups typically develop a wide variety of products, at which point the demands on moulding costs are extremely high.

The multi-station plastic vacuum (negative pressure) forming machine is a practical choice. It has a simpler structure, lower investment cost, and easier operation and maintenance. While suited for less complex containers, it still supports efficient production.