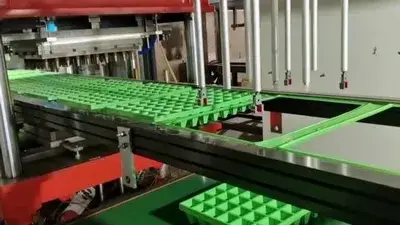

This three-station plastic vacuum forming machine uses negative vacuum pressure for molding. It is suitable for processing PS, PP, PVC, PET, HIPS, PC, and other plastic sheets into a wide range of shapes, including transparent, round, square, and irregular products. The roll-fed three-station thermoforming machine is ideal for producing various types of packaging such as boxes, plates, trays, bowls, lids, and more, with applications across food packaging, cosmetic packaging, industrial packaging, and general-purpose plastic products.

| Model |

|

|

| Max. forming area | 720×760mm | 720×850mm |

| Forming pressure | Negative vacuum pressure | |

| Applicable material | PET/PP(mix PE)/PS/PVC/ABS/PC | |

| Sheet thickness | 0.2-1.8mm | |

| Forming height | Female mold 0-80mm Male mold 0-150mm | |

| Production speed | 10-15 cycles/min | |

| Mold moving upward | Electric | |

| Eject-die | Shake to mould-down | |

| Power consumption | 25-40kW/hr | |

| Vacuum pump power | 4.0kW/150m³ | |

| Servo motor | 4.5/5.5/7.5kW | |

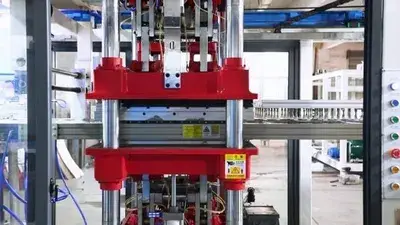

| Cutting force | 60t | |

| Cutting length | 11m | |

| Air consumption | 6.5kg/cm 1000-1500 liters/min | |

| Power supply | 380V 50Hz | |

| Machine dimensions (L×W×H) | 10000×2750×2660mm | 11000×2850×2660mm |

| Machine weight | 8500kg | 9500kg |

A machine integrating forming, punching, cutting and stacking functions.

Supports three-station punching of circular holes in the base.

Customers may select moulding dies made from plaster, copper or aluminium according to market demand and order requirements. Cutting dies may also be chosen from wooden or aluminium options, greatly facilitating independent market development and reducing production costs.

Moulds compatible with conventional vacuum forming machines may be utilised on this equipment, enabling traditional vacuum forming factories to avoid mould wastage.

Four-guide roller design with servo motor control ensures stable punching and cutting with balanced power

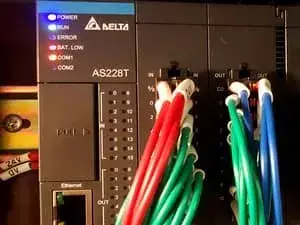

Touchscreen control panel

Touchscreen control panel Vacuum pump

Vacuum pump Servo system

Servo system Ceramic infrared heater

Ceramic infrared heater

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

The plastic thermoforming machine with positive and negative pressure forming is the preferred choice. It provides more uniform thickness and better material distribution, producing smoother surfaces and reducing internal stress. This results in higher transparency for finished products.

Start-ups typically develop a wide variety of products, at which point the demands on moulding costs are extremely high.

The multi-station plastic vacuum (negative pressure) forming machine is a practical choice. It has a simpler structure, lower investment cost, and easier operation and maintenance. While suited for less complex containers, it still supports efficient production.

Lunch takeaway boxes are typically manufactured from polypropylene (PP) material.

Should the factory require precise die-cutting with no burrs along the outer edges, we recommend employing single-station in-mould trimming machines.

Recommend HY-54/76 (760×540mm) or ATC-75/52 (750×520mm) models.

Where production volume demands take precedence over die-cutting precision, we advise utilising multi-station forming machines.

Recommend ATM-76/65 (760×650mm) or ATM-75/85 (750×850mm) models.

Our negative pressure three-station thermoforming machine boasts extensive case studies demonstrating its highly successful capability to simultaneously perform trimming, punching, and waste removal during the punching station for PS/PET products.