This thermoforming machine is designed to process PP, PS, HIPS, PET, and PVC sheets into a wide range of products such as plastic cups, lids, bowls, trays, plates. It is ideal for manufacturing disposable tableware and plastic cups such as cold drink cups, yogurt cups, jelly cups, ice cream cups, snack boxes, plastic bowls, and milk tea lids.

| Model |

|

|

|

| Forming area | 750×420mm | 750×520mm | 850×560mm |

| Power supply | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Applicable material | PP/PS/PET/PVC sheets | PP/PS/PET/PVC sheets | PP/PS/PET/PVC sheets |

| Drive | Hydraulic drive (cam drive is optional) | Hydraulic drive (cam drive is optional) | Hydraulic drive (cam drive is optional) |

| Stretching method | Air cylinder/servo motor | Servo Motor | Servo Motor |

| Samples of PP cups | Diameter 70mm, 30pcs/mold Diameter 95mm, 17pcs/mold |

Diameter 70mm, 38 pcs/mold Diameter 95mm, 24 pcs/mold |

Diameter 70mm, 45 pcs/mold Diameter 95mm, 28 pcs/mold |

| Samples of PET cups | Diameter 70mm, 30pcs/mold Diameter 95mm, 17pcs/mold |

Diameter 70mm, 30pcs/mold Diameter 95mm, 18pcs/mold |

Diameter 70mm, 36pcs/mold Diameter 95mm, 21pcs/mold |

| Sheet thickness | 0.20-2.0mm | 0.20-2.0mm | 0.20-2.0mm |

| Max. forming depth | ≦180mm (can be customized 180-250mm as per customer request) | ||

| Production speed | 15-30 cycles/min (without robot stacking) 12-18 cycles/min (with robot stacking) | ||

| Air pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Feeding motor power | 3.7kW | 4kW | 4kW |

| Main motor power | 11kW | 15kW | 15kW |

| Heating oven power | 141kW | 151kW | 168kW |

| Air consumption | 2400L/min | 2800L/min | 3000L/min |

| Machine dimensions (L×W×H) | 4000×1600×2500mm | 4000×1600×2500mm | 5200×1800×2800mm |

| Total power | ≤160kW | ≤170kW | ≤180kW |

| Power consumption | 50% of total power | 50% of total power | 50% of total power |

| Machine weight | 6500kg | 7500kg | 8500kg |

Optional hydraulic or cam mechanisms to accommodate varying user preferences

Choice of pneumatic cylinders or full servo control to meet diverse production requirements

Compact design facilitates transportation and reduces initial investment costs

Versatile production capabilities for manufacturing cups, bowls, lids and food containers

Forming and punching completed at the same workstation for simplified operation, ensuring precise punching with zero error, particularly suited for pure polypropylene products

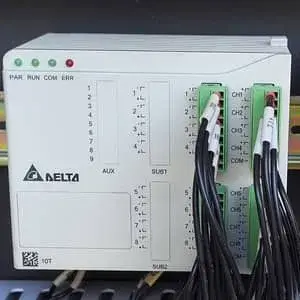

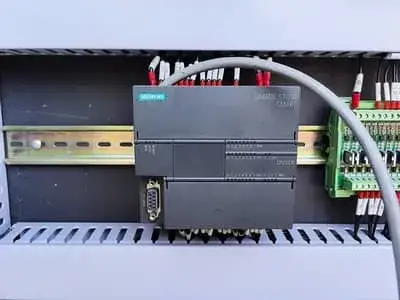

PLC system

PLC system Temperature module

Temperature module Relay

Relay Servo motor

Servo motor

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Typically, plastic cups and bowls are manufactured from highly transparent materials such as polypropylene (PP) and polyethylene terephthalate (PET). This demands exceptionally high standards in stretch forming technology, and our thermoforming machines for plastic cups can provide customers with production capabilities.

Yes, ice cream cup is made from PET material, this plastic cup forming machine supports thermoforming processes using polyethylene terephthalate (PET) materials, ensuring compliance with the hygiene standards and transparency requirements necessary for food packaging. It can be used to manufacture ice cream cups in a variety of complex shapes.