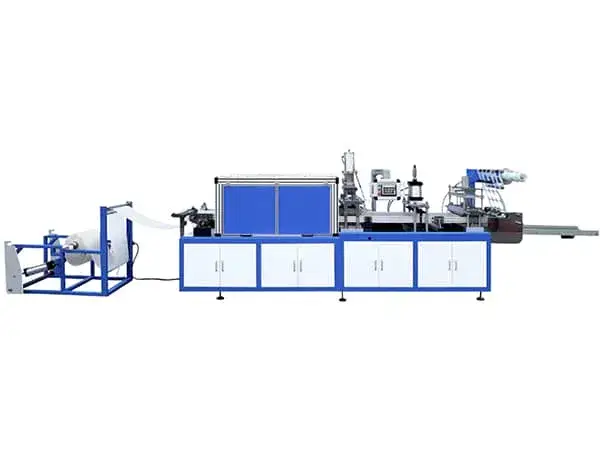

This thermoforming machine is designed to process PP, HIPS, PET, and PVC sheets into various types of cup lids and food container lids. In addition to lids, it can also produce small trays and similar packaging products, making it a versatile choice for disposable packaging manufacturers.

| Model |

|

| Max. forming area | 450×320mm |

| Max. forming depth | 45mm |

| Applicable material | PP/HIPS/PVC/PET/PS |

| Cutting frequency | 15-25 cycles/min |

| Stroke adjustable range | 0-160mm |

| Total power | 24kW |

| Air consumption | >0.2m³/min |

| Air pressure | 0.4-0.7MPa |

| Power supply | 380V/220V, 50Hz |

| Machine dimensions (L×W×H) | 5500×100×1900mm |

| Machine weight | 3200kg |

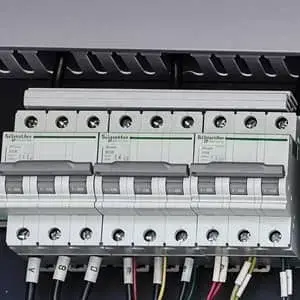

Circuit breakers

Circuit breakers PLC control system

PLC control system Frequency converter

Frequency converter

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Typically, plastic cups and bowls are manufactured from highly transparent materials such as polypropylene (PP) and polyethylene terephthalate (PET). This demands exceptionally high standards in stretch forming technology, and our thermoforming machines for plastic cups can provide customers with production capabilities.

Yes, ice cream cup is made from PET material, this plastic cup forming machine supports thermoforming processes using polyethylene terephthalate (PET) materials, ensuring compliance with the hygiene standards and transparency requirements necessary for food packaging. It can be used to manufacture ice cream cups in a variety of complex shapes.