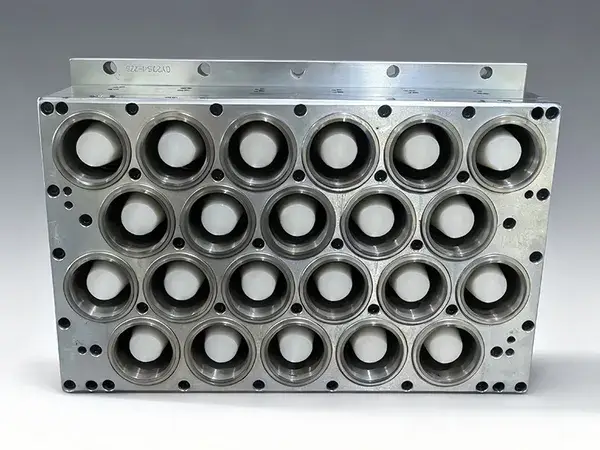

Thermoforming molds for plastic cup making machines provide durable tooling for the production of disposable plastic cups with high precision and offer both one-piece and independent designs to meet customer requirements.

Designed for use with plastic cup thermoforming machines.

For PP products, which are easier to cut, tooling can be made with Cr12MoV or SKD11 steel. For PET products, which require higher hardness, DC53 steel is used to ensure mold durability.

The standard mould employs a full-plate cutting edge design, which offers superior flatness, facilitates tool adjustment, and enhances overall precision.

For customers who prefer independent cutter tooling designs, we can also provide customized solutions. This approach may require a longer processing time but offers the advantage of easier tool replacement. All design details are fully discussed with the customer before processing.

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Typically, plastic cups and bowls are manufactured from highly transparent materials such as polypropylene (PP) and polyethylene terephthalate (PET). This demands exceptionally high standards in stretch forming technology, and our thermoforming machines for plastic cups can provide customers with production capabilities.

Yes, ice cream cup is made from PET material, this plastic cup forming machine supports thermoforming processes using polyethylene terephthalate (PET) materials, ensuring compliance with the hygiene standards and transparency requirements necessary for food packaging. It can be used to manufacture ice cream cups in a variety of complex shapes.