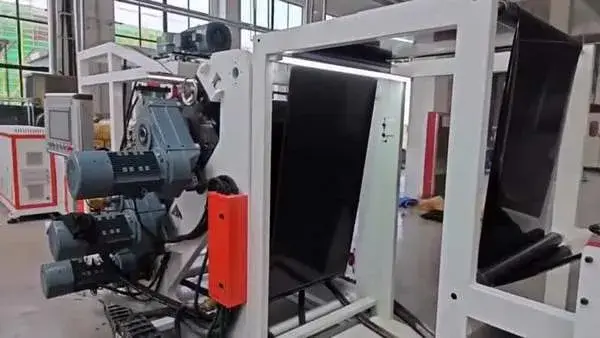

The PP/PS/PE plastic sheet extrusion machines are engineered to deliver high-quality and precise sheet production for diverse industries. By combining extrusion, calendering, and winding processes, the system converts raw plastic pellets into sheets or roll stock ready for thermoforming. Capable of processing PS, PP, and HIPS polymers, it supports applications such as plastic cups, bowls, trays, blister packs, and stationery packaging. With versatile performance and dependable operation, it provides manufacturers with a reliable solution tailored to meet various production needs.

| Model |

|

| Applicable material | PP/PS/PE |

| Sheet layers | 1-5 layers |

| Production capacity | 150-250kg/h (can be customized) |

| Screw diameter | Optional 120/130150mm |

| L/D ratio | 35:1, graded separation |

| Screw speed | 80rpm |

| Die width | 900mm |

| Effective sheet width | 780mm |

| Sheet thickness | 0.3-3.5mm |

| Main motor | 75kW |

| Upper calender | Ø450×900mm |

| Middle calender | Ø450×900mm |

| Lower calender | Ø450×900mm |

| Chiller calender | Ø200×900mm |

| Rewinding method | Independent winding |

| Max. rewinding diameter | 800mm |

| Total power | 180kW |

| Power supply | 380V, 3 phase, 50Hz |

| Machine dimensions (L×W×H) | 17×3×2.6m |

| Machine weight | 12t |

Adopts advanced horizontal three-roll calender technology, making operation simple and easy to monitor

High efficiency with large-capacity extrusion and low power consumption

Screw design with large L/D ratio ensures superior plasticizing performance

Ergonomically designed for ease of use, comprehensive functions, and reliable operation

Touchscreen control panel

Touchscreen control panel PLC system

PLC system Inverter

Inverter Contactor

Contactor

Partner with us for efficient, precise, and sustainable thermoforming and extrusion machines made to meet global market demands.

Contact us today!

Thermoforming machines are designed for different product types and production requirements. We recommend identifying your core product category first and then selecting equipment that best fits those needs. No single machine can cover every product in the market, focusing on your main products ensures efficiency and market success.

Common plastic packaging materials include PP, PET, PVC, HIPS, and BOPS:

By changing molds, the same machine can produce different products. The key condition is that the production volume and product specifications must meet the requirements of the chosen machine model.

Once your order is confirmed, we design the molds based on your product samples and share the drawings for your approval. After confirming the design and dimensions, we proceed with mold manufacturing.

Our standard payment options are T/T and L/C. If you require alternative methods, please contact us to discuss suitable arrangements.